- WHERE DO WE USE TECNOMATRIX PLANT SIMULATION SOFTWARES SOFTWARE

- WHERE DO WE USE TECNOMATRIX PLANT SIMULATION SOFTWARES WINDOWS

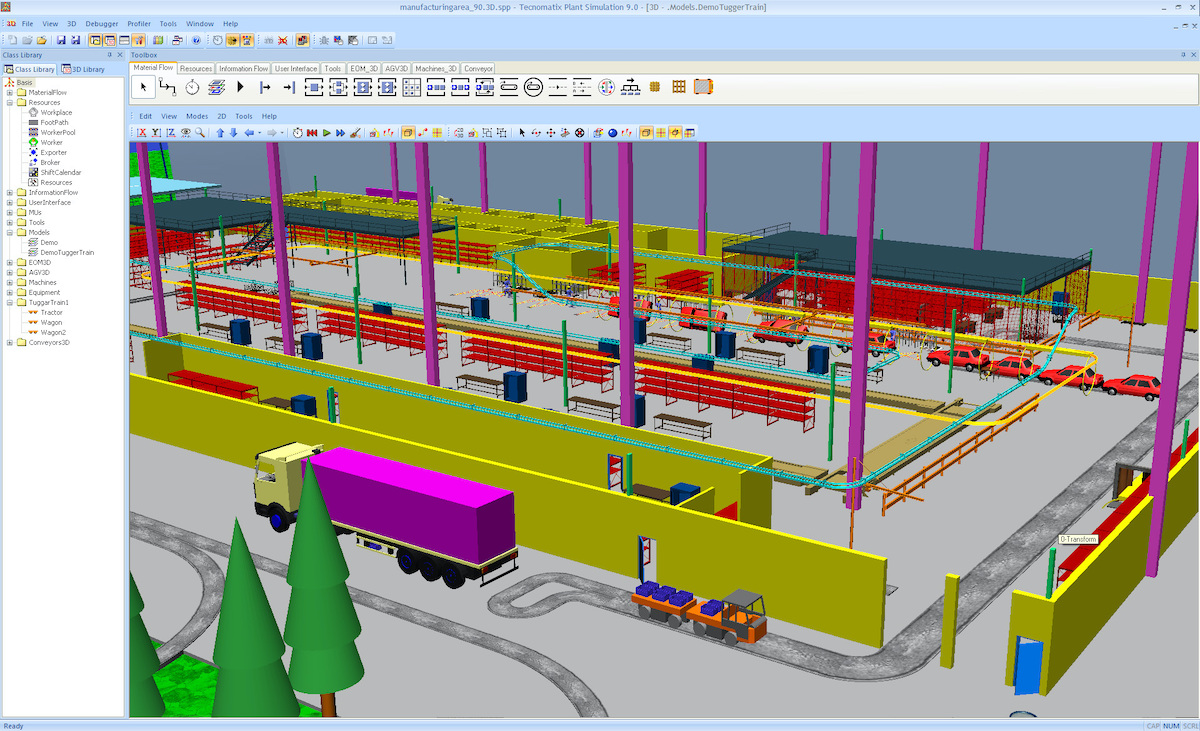

Lowered investment risks through early proof of concept.Optimized system dimensions, including buffer sizes.Reduced investment in planning of new facilities.Improved productivity of existing facilities.Plant Simulation supports the JT data format for 3D modeling, an International Standards Organization (ISO) standard, and Siemens PLM Software’s direct model technology, which enable efficient loading and realistic visualization of large 3D simulation models. The result is impressive 3D virtual models that are synchronized at all times with their 2D counterparts, allowing customers the flexibility to choose the appropriate method of visualization without compromising simulation and analysis needs. In addition to the highly efficient 2D model view of Plant Simulation, models may be visualized in a 3D virtual environment using included libraries or user specific computer aided design (CAD) data. Extensive statistics and charts can be generated to support dynamic analysis of performance parameters, including line workload, breakdowns, idle and repair time and proprietary key performance factors. Statistical analysis, graphs and charts display the utilization of buffers, machines and personnel. The simulation models take into consideration internal and external supply chains, production resources and business processes, allowing users to analyze the impact of different production variations. Plant Simulation models are used to optimize throughput, relieve bottlenecks and minimize work-in-process. Simulating and Analyzing System Performance Complex and detailed simulations can be handled, understood and maintained much better than in conventional simulation tools by using Plant Simulation architectural advantages such as capsulation, inheritance and hierarchy. Extending the library with company specific objects allows for the capture of best practice engineering experiences for further simulation studies. Users can choose from predefined resources, order lists, operation plans and control rules. Simulation models can be created quickly by using components from application object libraries dedicated to specific business processes, such as assembly or automotive body manufacturing processes.

WHERE DO WE USE TECNOMATRIX PLANT SIMULATION SOFTWARES WINDOWS

The intuitive, context-sensitive ribbon menu user interface of Plant Simulation follows Microsoft Windows standards, making it easy to get familiar and productive quickly. This is achieved through powerful object oriented architecture and modeling capabilities that enable customers to create and maintain highly complex systems, including advanced control mechanisms. Plant Simulation enables companies to create well structured, hierarchical models of production facilities, lines and processes. Source: Siemens Tecnomatix Plant Simulation Modeling Manufacturing Processes

Extensive analysis tools, statistics and charts let users evaluate different manufacturing scenarios and make fast, reliable decisions in the early stages of production planning. The digital model not only enables users to run experiments and what-if scenarios without disturbing an existing production system, but it can be used in the planning process long before the real system is installed. Plant Simulation helps to create digital models of logistics systems so companies can explore system characteristics and optimize their performance. The need to deliver on time and in sequence, introduce lean manufacturing principles, plan and build new sustainable production facilities, and manage global production networks requires objective decision criteria to help management evaluate and compare alternative approaches. In times of increasing cost and time pressures in production along with ongoing globalization, logistics has become a key factor in the success of a company. The simulation tool can be leveraged to analyze global facilities, an entire plant, or simply a few machines in a production line. Using Plant Simulation enables companies to optimize material flow, resource utilization, and logistics for all levels of plant planning.

WHERE DO WE USE TECNOMATRIX PLANT SIMULATION SOFTWARES SOFTWARE

Tecnomatix Plant Simulation software enables the simulation, visualization, analysis and optimization of production systems and logistics processes.

0 kommentar(er)

0 kommentar(er)